Two Types of Air Preheater

The temperature of gases leaving the economizer after heating the feed water is in the range of 250°C- 450°C. This heat energy in exhaust gases can be further utilized to preheat the surrounding air before supplied to combustion chamber. After transfer of heat to air, these gases are finally discharged to the surroundings through the chimney. Thus, an air preheater is a heat exchanger which is used to preheat the air before entering the furnace by utilizing the waste energy of gases.

Advantages of preheating the air are :

- It improves the rate of combustion of fuel and raises the flame temperature.

- The increased flame temperatures results into higher heat transfer rates from hot gases to heating surfaces of the boiler.

- It reduces the amount of excess air needed for complete combustion of fuel. In turn, it reduces the heat losses.

- It is possible to burn low grade fuels.

- It improves the boiler efficiency and saves the fuel cost. {Approx saving in fuel is 5% per (130°C-140°C) air temperature rise}

- The exit temperature of gases leaving the economizer being in the range of 150°C-200°C, it reduces the problem of acid corrosion and helps in removing the gases from the chimney.

These are as follows :

1. Recuperative type air preheaters.

2. Regenerative type air preheaters.

1. Recuperative air preheaters :

- In these type of air preheaters, the heat is directly transferred from the hot gases to the air across the heat transfer surface.

- These may be tubular or plate type.

- Usually tubular type of air preheater are used in practice.

- In these type, gas flows over the tube and air is passed over it or air may flow in the tubes and gases pass over the tubes. Because of low heat transfer coefficient of gases, the heat transfer rates are low.

- In order to improve the heat transfer rates either the surface area needs to be increased by using gilled tubes or flow velocities needs to be increased.

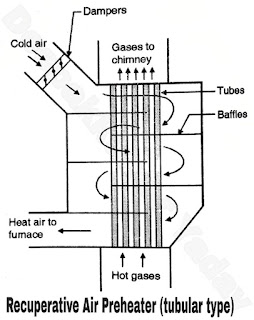

- The tubular counter flow heat exchanger is shown in Figure A.

- In this, the baffles are provided to maximize the air contact with the hot tubes.

- The diameter of tubes is decided based on heat transfer rates, cleaning requirement, the cost and the type of fuel used.

- Generally, 5 cm to 7 cm OD tubes are used in modern air preheaters In plate type air preheaters, hollow plates are welded electrically in which air is forced to flow while the gas flows in counter flow direction.

- These are not used in practice because of choking, corrosion and maintenance problems were faced.

Figure A

2. Regenerative air preheater :

- Regerative air preheaters are also called as storage type in which the heat is first transferred from hot flue gases to a storage medium in the form of matrix and then from matrix to the air.

- Thus, the matrix is alternately exposed to hot and cold fluids.

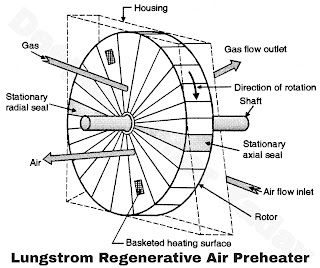

- The most common type of regenerative or rotary air preheater is Lungstrom air preheater. It is shown in Figure B.

- It is a compact heat exchanger with a large heat transfer surface being accommodated in a small volume.

- It consists of a rotor driven by a motor at low speed through reduction gears at about 2 to 4 rpm depending upon its diameter.

- Its rotor is divided into 12-24 radial sectors. Each sector is filled with flat or corrugated steel sheets. These sheets form the heat transfer surfaces.

- The stationary sealed sectors on opposite side of sectors prevent the leakages of gas and air in their respective paths.

- When the rotor rotates, the gas heats upper half of the heating surfaces.

- When it moves down after half rotation, the air passes over these heated sector and hot air is then flows out of rotor and the cycle repeats itself.

- Thus, it can be seen that the heat transfer from the gas to air is periodic.

|

| Figure B |

The disadvantages of regenerative air preheater are :

- Choking of flow openings by fly ash.

- Problem of sealing of gas and air paths.

- Large pressure drops.

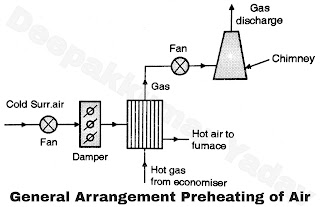

The general arrangement of preheating of air by gases in shown in Figure C. On one air preheater is shown in this system. However, in case higher air temperatures are needed, then two air preheaters are used. Primary air heater raises the temperature of air upto 150°C and in secondary air heaters, the temperature of air is further raised between 240°C to 340°C as needed in pulverized coal firing.

|

| Figure C |