Various Ash Handling Systems

Various ash handling systems used are :

- Hydraulic ash handling system.

- Pneumatic ash handling system.

- Mechanical system.

1. Hydraulic Ash Handling System :

- The schematic diagram of hydraulic ash handling system is shown in Figure A.

|

| Figure A |

- This site is med for larger power plant. In this system ash from the the furnace grate falls into a system of water possessing high velocity and it carries the ash to sumps.

- In the sumps water and ash are separated. The ash is the loaded into wagons a tracks by means of belt conveyor or grab buckets and transferred to dumpsite.

- The materials used for troughs and sumps has to be corrosion and wear resistant sine the ash dissolved in water forms acid.

- The advantage of this system is that it is clean, dustless and totally enclosed. It does not harm the men working on the system.

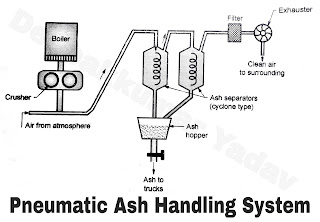

2. Pneumatic Ash Handling System :

- The schematic diagram of a pneumatic ash handling system is shown in Figure B.

- This system is used when the ash is required to be transported at a considerable distance from the site. The system can handle successfully the abrasive ash and fine dust.

- The ash from the boiler furnace falls into a crusher where large ash particles are divided into small particles.

- A high velocity air stream created by an exhauster carries all the ash and dust particles to primary separator which works on cyclone principle. The ash is collected in the ash hooper.

- The air with left over ash passes through the secondary ash separator and the air leaving this separator is passed though a filter fear removing the dust particles.

- Therefore the washed or clear air is only handled by the exhauster, This system is cheap. occupies less space, removes all the ash and the ash handled is in the dry state.

- The problem with this system is that its maintenance cost is high since the wear of pipe lines is high due to abrasive character of ash.

|

| Figure B |

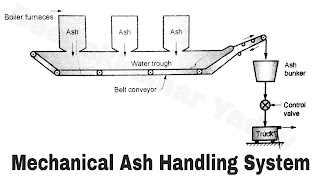

3. Mechanical Ash Handling System :

|

| Figure C |

- The schematic diagram of Mechanical ash handling system is shown in Figure C. This system is only used for low capacity power plants.

- The hot ash released from the boiler furnaces is allowed to fall over the belt conveyors after cooling it through water seal.

- This cooled ash is transported through belt conveyor and falls on to the ash bunker.

- From the ash bunkers, the ash is removed to the dumping site with the help of trucks.

4. Dust Collection System :

- In coal fired boilers the flue gases have certain particles of solid matter in suspension this is called smoke or dust. In case of pulverized coal furnaces the flyash remains in suspension with flue gases.

- If the particles in suspension are of size from 1 to 100 microns it is called dust or smoke and for particles size more than 100 microns, it is called cinder.

- Any dust particles leaving into chimney exhaust are objectionable and harmful for the health of human being and for plant life.

- The production of smoke in chimney exhaust is also indicative of incomplete or improper combustion of fuel, in turn, it is indicative of low thermal efficiency of the plant.

- Therefore, it is always necessary to clean the gas from dust, smoke or cinder particles before it is to be discharged from the chimney.