Pulverizing Mills

Pulverizing mills called pulverizers are used to convert the crushed coal into fine dust particles. It helps in promoting the rapid combustion of fuel and air.

Various pulverizing mills used are :

- Ball and race mill

- Bowl mill

- Ball mill

- Impact or hammer mill

The pulverizers are driven by electrical motors. Working of few pulverizers are explained below :

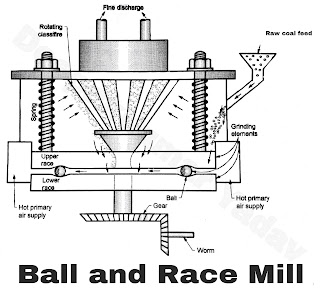

1. Ball and race mill :

- The schematic diagram of a ball and race is shown in Figure A.

- It is a low speed unit in which the grinding pressure is maintained by the springs. This is also known as contact mill. It consists of two elements which have rolling action with respect to each other.

- The coal is passed through these two elements again and again until it is powdered to the desired degree of fineness.

- Hot air is supplied to the mill through the annular space surrounding the two races with the help of a fan.

|

| Figure B |

- The air picks up the coal dust as it flow between the ball and races and then it enter into the rotating classifier above. The oversized particles are thrown out due to cyclonic action of air and coal particles to the wall of the classifier and only fine coal dust of required size is discharged from the top of classifier and supplied to the burners.

- This type of mill consumes about 14 to 16 kWh of energy per ton of coal pulverized.

2. Bowl mill :

- The bowl mill grinds the coal between an whirling bowl and rolls mounted on pivoted axes.

- Coal fed into the centre is thrown by centrifugal force against the sides of the bowl where it is pulverized between the sides of the bowl and the grinding ring.

- The fine and intermediate sizes are picked up from the top by an air current and carried into the separator above for classification. It consumes about 5 kWh electricity per tonne of coal.

3. Ball mill :

- Principle of operation of a ball mill is shown in Figure B. It consists of a large rotating drum which rotates between 100 to 200 rpm.

- It has large number of steel balls of sizes varying from 2.5 cm to 5 cm in diameter. The coal of 6 mm size is fed into drum by screw conveyor.

|

| Figure B |

- As the drum rotates, the balls are carried upwards to be dropped on the coal as result the coal is crushed and grinds into fine particles gradually. The fine coal dust is swept by the hot air supplied to the drum.

4. Hammer mills :

- The principle of operation of hammer mill is shown in Figure C.

- These mills have swinging hammers or bars, into the path of which is fed the coal to be pulverized.

- Grinding is done by a combination of impact on the large particles and attrition on the smaller ones. Hot air is given to dry the coal.

- These mills are excellent dryers. It is compact, low in cost and simple.

- Its maintenance is costly and the power consumption is high when fine powder is required. It's capacity is limited.

|

| Figure C |