Methods of Dust Collection in Thermal Power Plant

Following are the methods of dust collection generally used in thermal power plants using coal as a fuel

(a) The settling chamber

(b) Impingement separators

(c) Cyclone separators

(d) Fabric filters

(e) Electrostatic precipitators.

(a) Settling Chamber

In this method of dust collection the principle used is to decelerate below the free falling velocity of the particles in it.

(b) Impingement Separators

These type of separators work on the principle of initial effect produced on the parties when sudden change of direction of gas flow is made. In this are the particles which move along with the gas stream, the large portion having finite mass and momentum gas when a sharp turn is provided but continue its original direction of motion and fall behind.

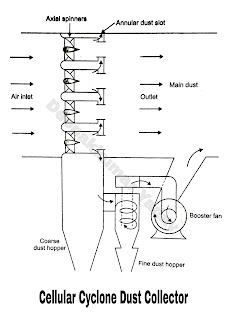

(c) Cyclone Separators

In this system a whirling column of gas is produced by means of axial tangential and into the cylindrical body. As the cylindrical body is rotated due to centrifugal force wing on the particles, It makes them to move to the periphery of gas stream and in the runs the collide with the walls of cyclone well, thus separating them due to their mass Figure A represents a cyclone type dust collector. It consists of an axial type vane inlet. This spins the gas and dust into helix due to centrifugal forces. It moves along the periphery of the cylinder. Here nearly 5 to 10% of the gas containing most of the dust particles move to primary hopper section. Here larger particles set down due to gravity. Then gas goes to the bank of secondary cyclones, where smaller particles are removed.

|

| Figure A |

The life of such filters depends upon operating temperature and surrounding conditions. They require Nigher operational temperatures, so as to avoid, alkaline dust, water dew points and 2018 dew points. Terylene is best material for filters, but it is decomposed by hydrogen chloride. The next suitable material is glass fibre but it is very weak mechanically.

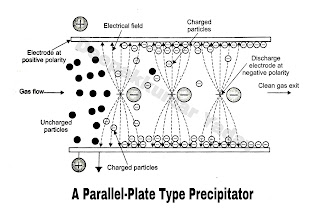

(e) Electrostatic Precipitator

In works on the principle, that when gas consisting of dust particles is made to flow into a chamber, where dust particles are given an electric charge and on passing through the electric held the charged particles are deflected on to collecting plates due to the electric force acting on them.

|

| Figure B |