Boiler

- The boilers used can be classified according to contents of tubular heating surface i.e. gas or water and accordingly are called as fire tube boilers and water tube boilers.

- It consists of tubes through which hot gases are passed and the water surrounds these tubes.

- It essentially consists of a shell which supports the fire tube and contain water for steam.

- As water and steam both are in the same shell, higher pressures of steam are not possible in their case.

- The maximum pressure which can be obtained is about 17.5 kg/cm and with a capacity of 9000 kg of steam per hour.

The advantages of Fire tube boilers are

(i) It is quite compact.

(ii) Fluctuations in steam demand can be met easily.

(iii) It's cost is low.

The disadvantages of Fire tube boilers are mainly

(i) It requires larger time for steam raising due to large quantity of water.

(ii) High pressure of steam is not possible.

(iii) Output of such boilers is limited.

(iv) Steam formed is generally wet.

Hence, such type of boilers are not used in thermal power plant of large capacity.

2. Water tube boilers

- They have less weight of metal for a given size, are less liable to explosion, they produce higher steam pressure, they respond quickly to changes in steam demand.

- Tubes and drums of water tube boilers are smaller than those of fire tube boilers.

- A pressure of 125 kg/cm can be obtained in their case with a high temperature of 315°C to 575°C are possible. They acquire less space and is easily accessible.

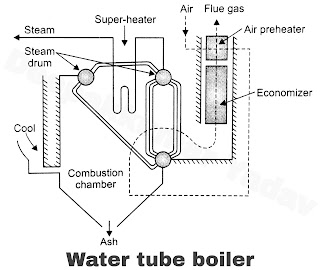

- Fig. 1.5 shows a water tube boiler in the simplest form. In this type of boiler heat transfer takes place through the walls of the tubes and the drum. The steam is heated to very high temperature in the superheater before passing through the boiler to the prime mover (turbines).

- The fuel is burned in the furnace of the boiler. For efficient combustion of fuel sufficient air is supplied either by natural draught provided by chimney and additional draught by I.D. or F.D. fans. Heat is generated by combustion of fuel. The gaseous products of combustion give their heat to the water in the tubes of the boiler and superheater.

- In order to make use of remaining heat in the gases they are made to pass through economizer, thereby heating the feed water in the economizer tubes.

- These gases are then made to pass through an air heater arrangement, providing initial heat to the air before it goes to the furnace.

- Then the gases are allowed to pass out to the atmosphere through the chimney.

- For proper burning of fuel, air is supplied through F.D. fans below the grate. The ash pits receive the burnt fuel in the form of ash and clinker.

- The water tube boilers are available in a number of different designs, they may be straight or bent tube type, longitudinal or cross-drum type, horizontal tube type, vertical or inclined tube type or natural circulation, single or multi-drum type etc.

- Special designs of boilers using high steam pressures, using forced circulation are developed.

- Most of the conventional water tube boilers depend upon natural circulation of water through the tubes.

- A number of accessories are fitted to the boiler such as water level indicators, feed water regulators, safety valves, blow down valves, automatic alarms, pressure gauges etc. Use of these assists in adequate control and operation of the boiler and also in safety against accidents.