Types of MHD Power Plants

The operation of MHD systems are broadly divided as follows :

- Open cycle system

- Closed cycle system

1. Open Cycle MHD System :

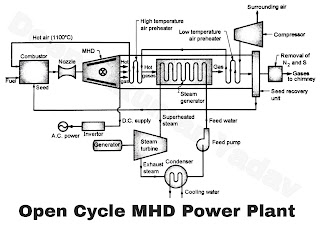

Figure A shows an open cycle MHD power plant.

The system uses an MHD generator in conjunction with conventional steam power plant. The fuel used may be coal, oil or natural gas.

The surrounding air is compressed to a high pressure in the air compressor. The gases are then heated in the low temperature and high temperature air preheaters before supplied to the combustion chamber upto a temperature of about 1100°C.

The fuel is burnt in presence of hot air in combustor. The hot gases so produced are seeded with 1% alkaline potassium to increase the electrical conductivity of the gases. These hot gases expand in the nozzle to high velocity and enter into MHD duct at about 2300°C to 2700°C temperature. Some part of the internal energy of the gas (plasma) is directly converted into DC power. Then DC-AC inverter converts the DC power into AC power.

|

| Figure A |

2. Closed Cycle MHD System :

Closed cycle MHD generators can either operate on seeded inert gas (helium or argon) system or liquid metal system. These systems are being discussed below.

1. Seeded Inert gas MHD generator : Figure B shows the closed cycle scheme using helium or argon gas seeded with Cesium MHD generator.

Inert gas helium seeded with Cesium is heated to a very high temperature in a nuclear reactor. The hot helium gas is passed into nozzles to increase its velocity before supplied to MHD duct to produce D. C. power which is converted into A. C. power by an inverter. The gas is passed through a heat exchanger called steam generator to convert feed water into steam to be used in the conventional steam power plant as shown in Figure B.

|

| Figure B |

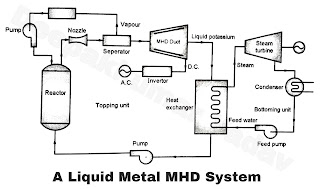

2. Liquid metal MHD system :

A liquid metal MHD system based on closed cycle is shown in Figure C. It is similar to inert gas system except that it uses liquid metal (potassium) instead of helium gas as the working fluid.

Liquid potassium is heated in the nuclear reactor is passed through the nozzles to increase its velocity. Small amount of vapour formed during the nozzle passage is separated in the separator and it is pumped back into the reactor. High velocity liquid metal is passed through the MHD duct to produce D. C. power.

Comparatively lower temperature liquid potassium is then passed through a heat exchanger (steam generator) before pumped to the reactor. It transfers heat to feed water which is converted into steam. This steam is used in a conventional steam power as shown in Figure C.

|

| Figure C |